sealing and filling capping machine for 4 heads

Filling capping machine is my factory specifically for the pharmaceutical and chemical manufacturers to develop the latest generation of the third generation of products, in the 1,2 generation on the basis of the increase in the automatic bottle and automatic cover function, to achieve a mechanical automation for the production enterprises Reduce labor costs. This model is mainly used for plastic bottles for packaging containers, pharmaceutical eye drops, (curing agent) instant glue products for quantitative filling and capping. The machine is mainly filling pharmaceutical eye drops, (curing agent) instant glue and other products.

work process

Automatically insert the plastic bottle into the indexing tube seat, the use of mechanical transmission, photoelectric detection device to confirm the plastic bottle in the working position, the material will be quantified by the metering pump into the bottle (bottle filling no bottle Installed), and then use the vibration plate automatic cover, the capping mechanism of the plastic bottle to cover, cover the finished product automatically ejected.

Automatic bottle automatic quantitative filling automatic cover automatic screw cap automatically ejected

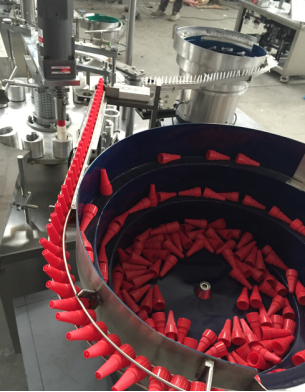

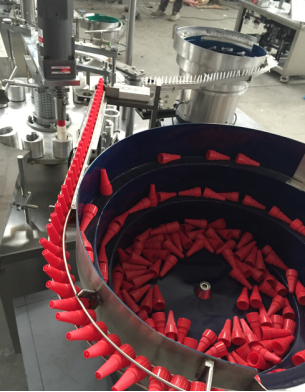

(1) on the bottle

The bottle is usually passed through the automatic bottle machine or vibration plate to the plastic bottle along the track is good, automatically the bottle into the mold. Only need to manually put the bottle into the vibration plate can be, bottle speed, bottle stability, with a noise shield noise

(2) filling

Filling with pressure filling and plunger filling two.

Pressure filling is the material into a closed container, through the pressure of the material squeezed to the mouth. The flap is equipped with a pneumatic valve to control the filling volume by adjusting the opening time of the pneumatic valve. Oxygen or water sensitive adhesive, sealed hopper should be filled with nitrogen;

Plunger filling is actually through the plunger pump, the material from the hopper and then re-injection bottle. The plunger is filled by adjusting the piston stroke to control the filling volume.

(3) cover

The cover is picked up by the robot from the cover to the bottle. The caps for the adhesive are long and are easily drained at the conversion station, so the robot must be screwed in.

(4) screw cap

The cap, which has been substantially rotated at the time of the cover, is tightened at the capping station. The capping station can adjust the tightness.

(5) off the assembly line

Filling capping process is completed, the next line will be finished bottle top, the bottle slide along the slide into the next packaging process or directly into the finished product box

The main technical parameters

(1) Production capacity: 30 ~ 50 / min (adjustable)

(2) filling capacity: 1 ~ 5ml, 5 ~ 50ml, 100 ~ 100 ml

(3) bottle specifications: diameter φ9 ~ 100mm length 20 ~ 280mm

(4) Motor power: 1.1 KW

(5) compressed air: 0.2 ~ 0.4Mpa

(6) Air consumption: 0.05M3 / min

(7) Input power supply voltage: 220V 50HZ

(8) Dimensions (mm): 1340 × 1200 × 1950

.